The 3D printing industry is undergoing a transformative shift toward sustainability, driven by growing environmental concerns and the demand for eco-friendly manufacturing solutions. At the forefront of this movement is the development and adoption of recyclable and biodegradable materials. These innovative materials are redefining additive manufacturing by reducing waste, lowering carbon footprints, and enabling circular production models. This article explores the rise of recyclable and biodegradable materials in 3D printing, their applications, challenges, and their potential to shape a sustainable future.

The Rise of Sustainable Materials in 3D Printing

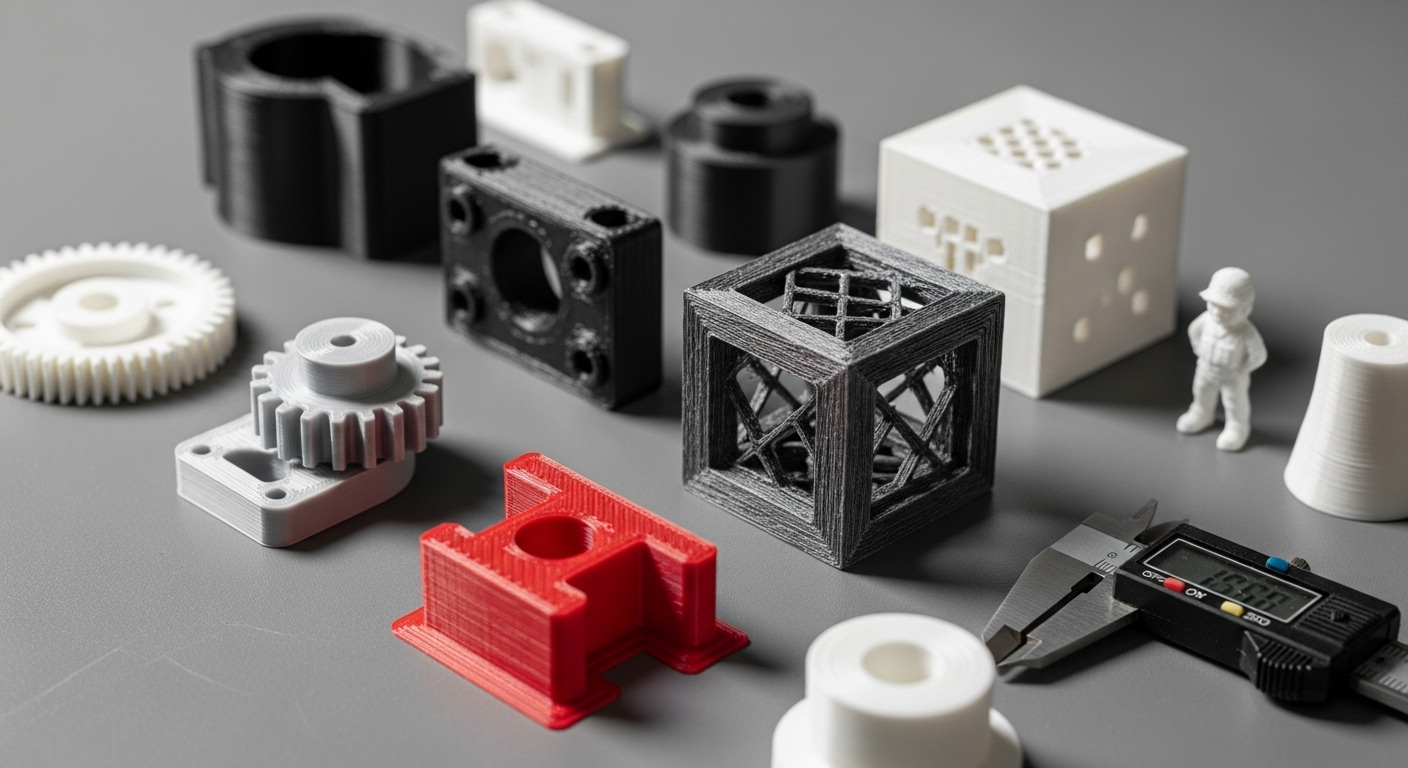

As global industries face pressure to address climate change and resource depletion, 3D printing—also known as additive manufacturing—offers a unique opportunity to minimize environmental impact. Unlike traditional manufacturing, which often involves wasteful subtractive processes, 3D printing builds objects layer by layer, using only the necessary material. The integration of recyclable and biodegradable materials further enhances this efficiency, aligning the technology with circular economy principles.

Recyclable materials, such as recycled plastics and metals, can be reprocessed and reused in 3D printing, reducing the demand for virgin resources. Biodegradable materials, like polylactic acid (PLA) and other bio-based polymers, naturally break down under specific conditions, leaving minimal environmental residue. Together, these materials are driving a paradigm shift in industries ranging from consumer goods to aerospace.

Key Materials and Innovations

Recyclable Materials

Recyclable materials in 3D printing are typically derived from post-consumer or industrial waste. Common examples include:

- Recycled PET (rPET): Sourced from plastic bottles and packaging, rPET is processed into filaments for 3D printing. It offers comparable strength to virgin PET while significantly reducing waste.

- Recycled Polypropylene (rPP): Often used in automotive and packaging applications, rPP is durable and recyclable, making it ideal for functional prototypes and end-use parts.

- Metal Powders: In metal 3D printing, excess powders from processes like selective laser melting (SLM) can be collected, filtered, and reused, minimizing material loss.

Innovations in recycling processes have improved the quality of these materials, ensuring they meet the performance standards required for demanding applications. For instance, companies are developing closed-loop systems where 3D-printed parts are shredded, reprocessed, and reprinted, creating a sustainable cycle.

Biodegradable Materials

Biodegradable materials are designed to decompose naturally, reducing long-term environmental impact. Key examples include:

- Polylactic Acid (PLA): Derived from renewable sources like corn starch or sugarcane, PLA is the most widely used biodegradable filament in 3D printing. It is compostable under industrial conditions and suitable for consumer products like packaging and disposable utensils.

- Polyhydroxyalkanoates (PHA): Produced by microorganisms, PHA is a versatile biodegradable polymer that decomposes in soil or marine environments, making it ideal for applications where end-of-life disposal is a concern.

- Bio-based Composites: Combining biodegradable polymers with natural fibers like hemp or flax, these composites enhance strength and sustainability while maintaining eco-friendly properties.

Recent advancements have expanded the performance capabilities of biodegradable materials, enabling their use in more complex applications, such as medical implants and automotive components.

Applications Across Industries

The adoption of recyclable and biodegradable materials is transforming a wide range of industries:

- Consumer Goods: Companies are using recycled PET and PLA to produce sustainable packaging, home decor, and fashion accessories. For example, 3D-printed shoes made from recycled plastics are gaining popularity for their eco-friendly appeal.

- Medical Sector: Biodegradable materials like PLA and PHA are used to create temporary implants and surgical guides that naturally dissolve in the body, reducing the need for follow-up surgeries.

- Aerospace and Automotive: Recycled metals and lightweight composites reduce the weight of parts, improving fuel efficiency and lowering emissions. These industries also benefit from the ability to recycle excess material during production.

- Construction: Large-scale 3D printing with recycled concrete or bio-based materials is being explored for sustainable building solutions, such as affordable housing and infrastructure.

These applications demonstrate the versatility of sustainable materials, enabling industries to meet environmental goals without compromising performance.

Challenges and Limitations

Despite their promise, recyclable and biodegradable materials face several challenges:

- Material Performance: Recycled materials may have inconsistent properties compared to virgin materials, requiring advanced processing to ensure quality. Biodegradable materials like PLA can be brittle, limiting their use in high-stress applications.

- Cost and Scalability: The production of high-quality recyclable and biodegradable materials can be expensive, particularly for specialized polymers like PHA. Scaling these materials to meet industrial demand remains a hurdle.

- Recycling Infrastructure: Effective recycling requires robust collection and processing systems. In many regions, the lack of infrastructure limits the availability of high-quality recycled feedstocks.

- Degradation Conditions: Biodegradable materials often require specific conditions, such as industrial composting facilities, to break down effectively. This can limit their environmental benefits in areas without such facilities.

Addressing these challenges requires ongoing research, investment in recycling infrastructure, and collaboration between material scientists, manufacturers, and policymakers.

The Future of Sustainable 3D Printing

The future of recyclable and biodegradable materials in 3D printing is bright, with several trends poised to accelerate their adoption:

- Material Innovation: Researchers are developing new bio-based polymers and composites with improved strength, flexibility, and thermal resistance, expanding their use in demanding applications.

- Closed-Loop Systems: Advances in recycling technology are enabling fully circular production models, where 3D-printed products are recycled and reprinted with minimal material loss.

- Policy and Regulation: Governments and organizations are introducing incentives and regulations to promote sustainable manufacturing, encouraging the adoption of eco-friendly materials.

- Consumer Awareness: Growing demand for sustainable products is pushing companies to prioritize recyclable and biodegradable materials, driving market growth.

As these trends converge, the 3D printing industry is likely to become a leader in sustainable manufacturing, setting a precedent for other sectors.

Conclusion

Recyclable and biodegradable materials are at the heart of the 3D printing industry’s sustainability revolution. By reducing waste, conserving resources, and enabling innovative applications, these materials are paving the way for a greener future. While challenges remain, ongoing advancements in material science, recycling infrastructure, and industry collaboration are unlocking their full potential. As the demand for sustainable solutions grows, recyclable and biodegradable materials will continue to shape the evolution of 3D printing, proving that innovation and environmental responsibility can go hand in hand.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.