PolyJet™ Multi-Colour 3D printing

What is PolyJet™ Multi-colour 3D printing?

PolyJet is a revolutionary multi-material jetting photopolymer 3D printing technology that brings your ideas to life with exceptional precision and versatility. From prototyping to production, PolyJet offers a wide range of capabilities, including the creation of complex geometries, intricate details, full-color combinations, transparencies, and flexible parts - all in a single model.

Explore the Diverse Industries Harnessing PolyJet™

Getting to Know the PolyJet Materials

PolyJet printing materials can be printed as single, base material, or they can be mixed to create composite materials, or digital materials.

The J850 Prime can produce over 600,000 PANTONE® validated color combinations, print seven resins simultaneously and provide multi-material capabilities that bring your most imaginative ideas to life.

Get A QuoteThe files that we currently accept are: STL, OBJ, VRML, STP, IGS or WRL. We do also able to turn your sketch into a workable 3D design.

The maximum printable area is 490 x 390 x 200 mm.

High Quality: up to 7 base resins, 14-micron resolution;

High Mix: up to 7 base resins, 27-micron resolution;

High Speed: up to 3 base resins, 27-micron resolution;

Super High Speed: 1 base resin, 55-micron resolution.

We charge for the material, the time the tool is used and the staff time. Most of the cost is due to the material and the time to print, and that depends on

(1) the size of your model;

(2) your choice of material;

(3) the orientation of the device as it prints.

For small printed device that is 1 cm tall, they use a couple grams of material only and an hour to print. The cost is about HKD 100.

For example: To print a human figure with Vero RGD material in the size 8cm tall would be around HKD 300.

We have the full Stratasys PolyJet materials from the complete Vero and Agilus range are available.

All of the materials, except the High‐temperature RGD 525 start to melt around 42‐45 °C. RGD 525 can

withstand 75‐80 °C. This may require a post‐printing heat treatment step.

Print time is determined by the number of vertical layers and the overall area covered on the print tray. So the taller the device, the longer it takes.

Quick jobs take about an hour including warm‐up time. A solid iPhone‐sized device would take 6 to 8 hours depending on the material.

Respecting your privacy is paramount to us, and we won’t showcase your prints on social media or our websites without explicit consent. Understanding the need for formal documentation, we can furnish a pre-signed NDA or evaluate and sign yours upon request. Feel free to reach out for NDA reviews.

dot 3D FACTORY acquires our own 3D printing eqipments and local workshops in Hong Kong. Most orders are shipped within 3-5 days subject to print and post process time. The turnaround time is consistently fast despite the occasionally lengthy print process, this is a differentiator for the bureau that we take a lot of pride in.

Great design don't just happen - they take a lot of effort, planning and imagination to achieve. From concept validation and design verification to testing functional performance, using modesl in each stage of the design process can revolutionise a designer's work.

Capturing the complexities of geometry and the intricacies of design, this dynamic design was transformed from imagination to reality with multi-material 3D printing.

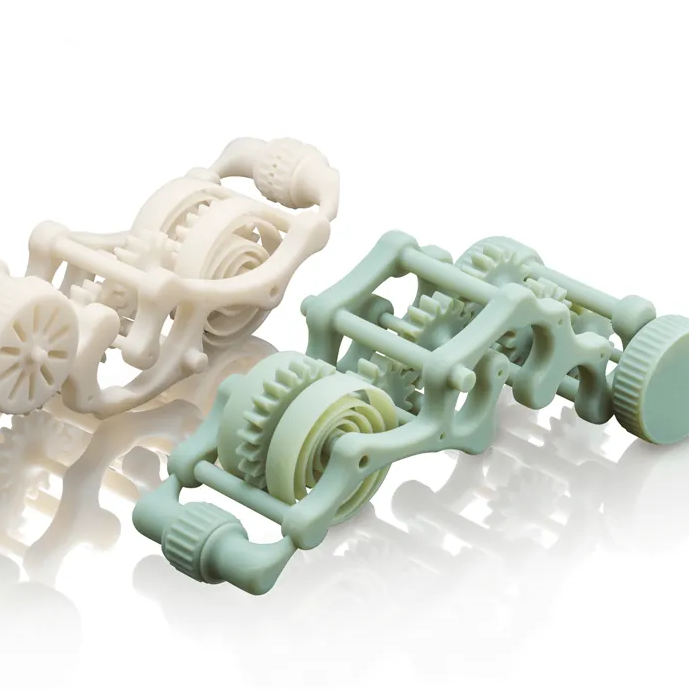

Just imagine what you could make. Bound by no design limits, these notebook covers explore CMF and the creative possibilities of multi-material 3D printing including colour, transparency and texture.

Great design don't just happen - they take a lot of effort, planning and imagination to achieve. From concept validation and design verification to testing functional performance, using modesl in each stage of the design process can revolutionise a designer's work.

Capturing the complexities of geometry and the intricacies of design, this dynamic design was transformed from imagination to reality with multi-material 3D printing.

Just imagine what you could make. Bound by no design limits, these notebook covers explore CMF and the creative possibilities of multi-material 3D printing including colour, transparency and texture.