In the world of additive manufacturing, Selective Laser Sintering (SLS) stands out as a powerful technology that enables the creation of robust, functional parts with intricate geometries. At dot 3D FACTORY, we are proud to offer SLS 3D printing services utilizing Formlabs' advanced SLS technology, specifically designed to work with high-performance nylon materials. This article explores the capabilities of SLS nylon 3D printing and highlights the various applications where this technology excels.

Understanding SLS Nylon 3D Printing

The SLS Process

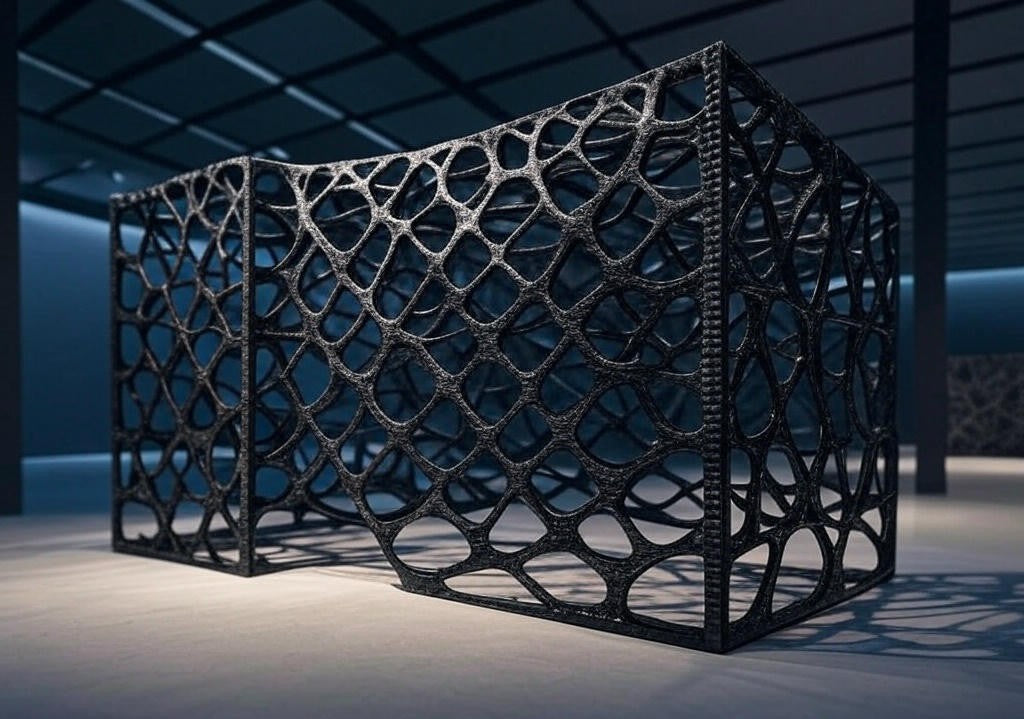

Selective Laser Sintering (SLS) is an additive manufacturing process that uses a high-powered laser to fuse small particles of polymer powder, layer by layer, to form solid structures. The process begins with a thin layer of nylon powder spread across the build platform. The laser then selectively sinters the powder according to the digital design file, fusing the particles together. This process is repeated layer by layer until the entire object is built.

Advantages of SLS Nylon Printing

-

Complex Geometries: SLS technology allows for the creation of complex, intricate geometries that would be difficult or impossible to achieve with traditional manufacturing methods.

-

No Support Structures: Unlike other 3D printing methods, SLS does not require support structures because the unsintered powder supports the part during printing. This leads to greater design freedom and easier post-processing.

-

Durability and Strength: Nylon is known for its excellent mechanical properties, including high strength, toughness, and resistance to wear and impact. Parts produced with SLS nylon are durable and can withstand rigorous use.

-

Functional Prototypes and End-Use Parts: SLS nylon printing is ideal for producing both functional prototypes and end-use parts, making it a versatile solution for various industries.

Formlabs SLS Technology

Formlabs is a leader in the 3D printing industry, renowned for its high-quality printers and materials. Their SLS technology, particularly the Fuse 1 printer, is designed to deliver professional-grade results with user-friendly operation. The Formlabs Fuse 1 printer combines precision, reliability, and affordability, making SLS printing accessible to a wide range of users.

Real-World Applications of SLS Nylon Printing

-

Product Development: For designers and engineers, SLS nylon printing offers the ability to create functional prototypes that closely mimic the mechanical properties of final production parts. This allows for thorough testing and validation of designs before moving to mass production.

-

Automotive and Aerospace: The automotive and aerospace industries benefit from SLS nylon printing by producing lightweight, strong components that can withstand harsh conditions. This technology enables the manufacturing of custom, low-volume parts with complex geometries, reducing weight and improving performance.

-

Medical Devices: SLS nylon printing is used to produce medical devices and prosthetics that require precise, custom-fit components. The biocompatibility and strength of nylon make it suitable for medical applications where durability and patient comfort are critical.

-

Consumer Products: From sporting goods to electronic enclosures, SLS nylon printing allows for the creation of durable consumer products with high-quality finishes. The ability to produce intricate designs and functional parts in small batches is particularly advantageous for startups and small businesses.

Why Choose dot 3D FACTORY for SLS Printing Services

At dot 3D FACTORY, we specialize in providing top-tier SLS printing services using Formlabs' state-of-the-art technology. Our team of experts is dedicated to helping you realize your projects with precision and efficiency. Whether you need a single prototype or a series of production parts, we have the expertise and equipment to deliver outstanding results.

Conclusion

Selective Laser Sintering (SLS) nylon 3D printing with Formlabs technology offers unparalleled advantages for producing durable, functional parts with complex geometries. At dot 3D FACTORY, we are committed to bringing this cutting-edge technology to your fingertips, providing you with the tools to innovate and succeed. Contact us today to learn more about our SLS printing services and how we can help bring your ideas to life.

Elevate your projects with the precision, strength, and versatility of SLS nylon 3D printing. Partner with dot 3D FACTORY and harness the power of advanced additive manufacturing to transform your vision into reality.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.