3D Printing's Shift to Mass Production: Reshaping Aerospace, Automotive, and Medical Supply Chains

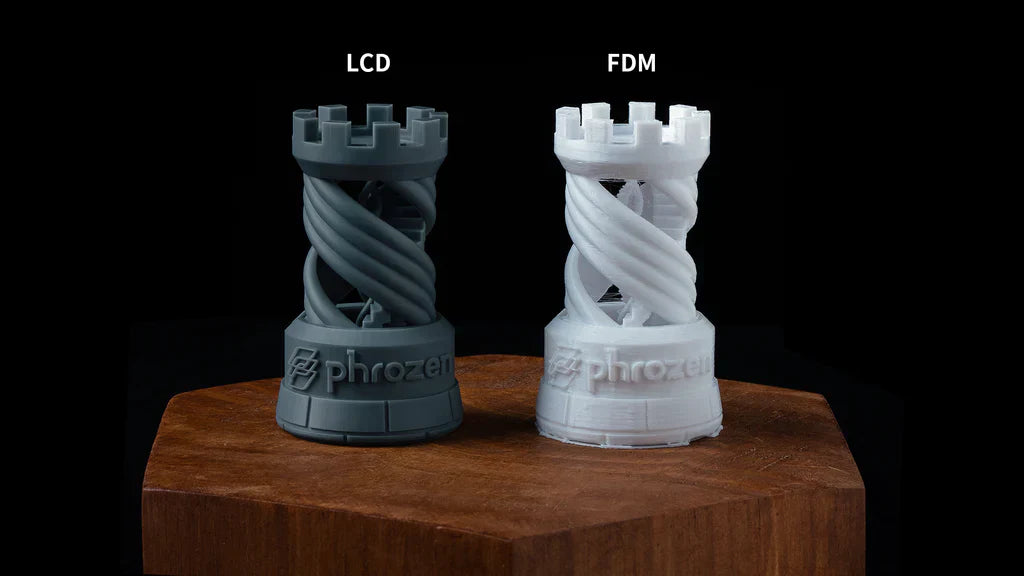

3D printing has transitioned from rapid prototyping to certified mass production in aerospace, automotive, and medical devices, driven by advances in multi-laser systems, hybrid manufacturing, and high-throughput printers that match traditional methods in speed and cost for medium volumes. This evolution supports end-use parts like lightweight engine components and patient-specific implants at industrial scales. Supply chains gain agility through localized production and reduced tooling, while jobs shift toward high-skill roles in AI monitoring and process optimization.

Aerospace: Certified Flight-Ready Parts

Aerospace leads with topology-optimized, lightweight components such as GE's fuel nozzles, Boeing's brackets, and Rolls-Royce's recycled titanium engine parts for the Orpheus engine, achieving 25% weight reductions and passing flight certifications. These shift from prototypes to production runs via metal powder bed fusion and hybrid additive-subtractive machines, cutting lead times from months to days. Firms like SpaceX integrate them for fuel efficiency in rockets and aircraft.

Automotive: Tooling and EV Components

Automotive manufacturers like Ford use 3D printing for high-volume tooling, jigs, and production parts in electric vehicles, slashing prototype times from months to days and enabling rapid design iterations. Serial programs for spare parts and lightweight structures blur prototyping and production lines, with layerless centrifugal printing nearing injection molding speeds for medium batches. This supports on-demand local production, reducing global shipping dependencies.

Medical Devices: Mass Customization at Scale

Healthcare produces patient-specific implants, prosthetics, surgical guides, and dental restorations using biocompatible materials, with digital workflows enabling industrial volumes and 17.5% CAGR through 2029. Mass customization streamlines hospital inventories by replacing off-the-shelf stock with precise, on-demand devices that improve outcomes. AI-assisted design and real-time quality control ensure repeatability for orthopedics and bioprinting.

Supply Chain and Job Impacts

On-demand 3D printing decentralizes production, shortening supply chains by enabling local factories to make complex parts without molds or long-lead imports, boosting resilience amid disruptions. It cuts waste and material costs via recycling, as in Rolls-Royce's titanium powder loops. Jobs evolve: over 1.3 million professionals now employed, with 80,000+ added yearly, focusing on AI defect detection, generative design, and certified AM operations rather than manual labor. This creates demand for skilled engineers in high-value sectors.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.