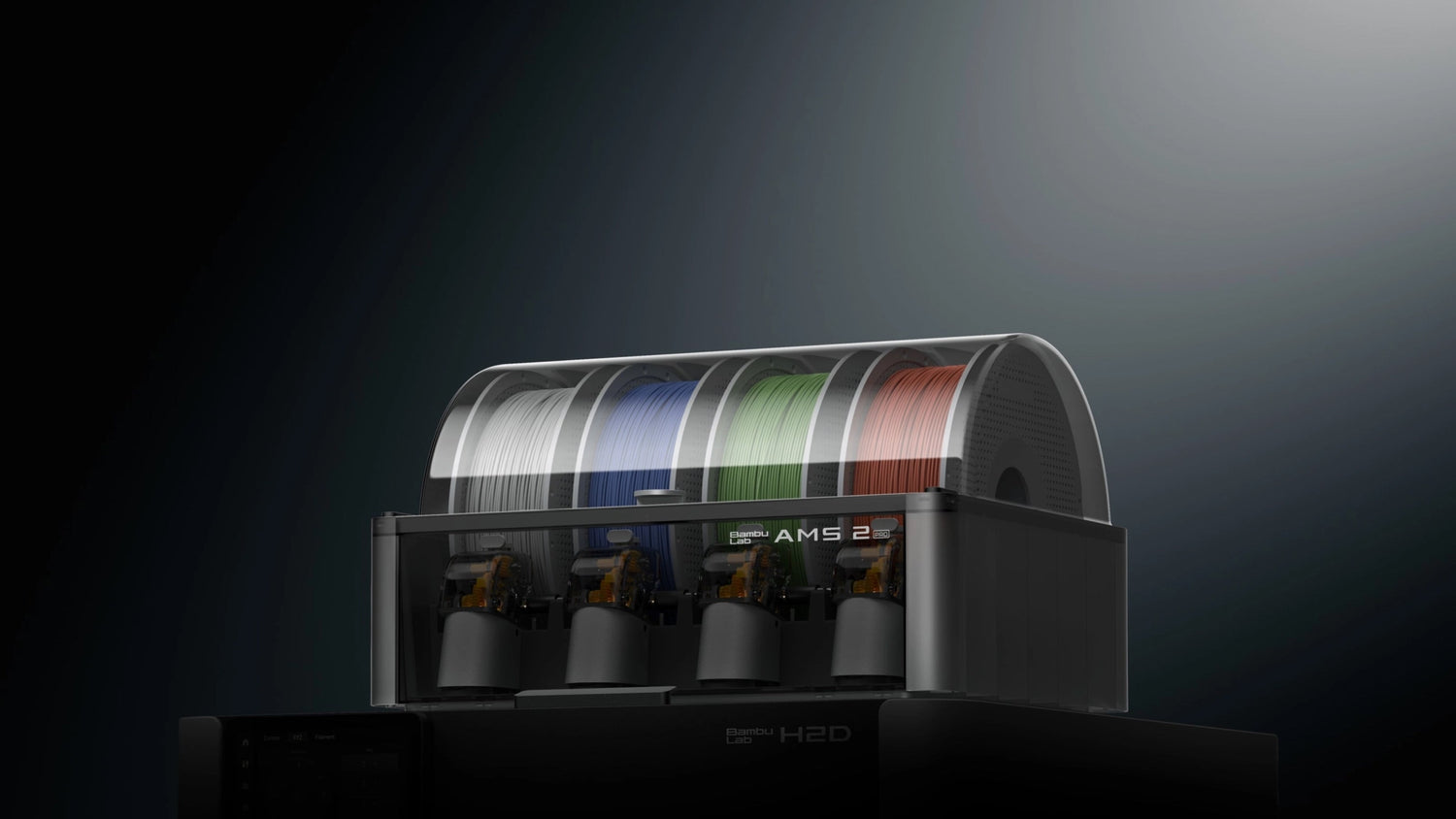

Bambu Lab’s Automatic Material System (AMS) 2 Pro is a groundbreaking advancement in 3D printing, offering unmatched capabilities for multi-color and multi-material printing. With the ability to manage up to 24 filaments by connecting multiple units, the AMS 2 Pro is designed to streamline workflows, improve print quality, and unlock new creative possibilities. Central to its functionality is the enhanced four-filament spool system and its seamless integration with the Bambu Lab H2D printer, which together redefine efficiency in 3D printing. This article delves into the specifics of the AMS 2 Pro’s filament management and its synergy with the H2D, highlighting how these features transform the 3D printing process.

Key Features of the AMS 2 Pro

Enhanced Four-Filament Spool System

The AMS 2 Pro’s core innovation lies in its ability to manage four filament spools per unit, a significant upgrade over traditional single-filament or manual-switching systems. Each spool slot is designed to accommodate a wide range of filament types, including PLA, PETG, ABS, ASA, PC, and dissolvable supports like PVA and BVOH (when properly dried). Key aspects of the four-filament spool system include:

-

Independent Filament Paths: Each of the four spools has a dedicated filament path with ceramic inlets (Vickers hardness of 1200) to minimize wear and ensure smooth feeding. This reduces the risk of filament jams and ensures consistent extrusion, even during high-frequency material switches.

-

Active Drying for All Spools: The AMS 2 Pro features dual drying modules with heaters and fans that maintain temperatures up to 65°C. An internal air circulation system ensures uniform drying across all four spools, while an electromagnetic air vent automates dehumidification. The spools rotate automatically during drying to eliminate moisture evenly, preserving filament quality for weeks.

-

RFID Integration for Automation: Each spool slot supports RFID recognition for Bambu Lab filaments, automatically syncing material settings (e.g., temperature, drying time) with Bambu Studio software. For third-party filaments, users can manually configure settings, ensuring compatibility with a broad range of materials.

-

Tool-Free Maintenance: The AMS 2 Pro’s top-access design allows users to address filament jams or perform maintenance without tools, unlike the first-generation AMS, which required disassembly. This reduces downtime and enhances usability, especially for complex multi-material prints.

By supporting four spools per unit, the AMS 2 Pro enables users to create intricate designs with multiple colors or materials in a single print job, eliminating the need for manual filament swaps and reducing post-processing.

Integration with the Bambu Lab H2D Printer

The Bambu Lab H2D, a dual-nozzle 3D printer with a large 420 x 420 x 420 mm build volume, is designed to maximize the potential of the AMS 2 Pro. The synergy between the AMS 2 Pro’s four-filament spool system and the H2D’s advanced hardware significantly enhances 3D printing efficiency in the following ways:

1. Dual-Nozzle Printing with Automated Material Switching

The H2D’s dual-nozzle system allows simultaneous printing with two different materials or colors, one per nozzle. When paired with the AMS 2 Pro, each nozzle can access any of the four filaments in a single AMS unit (or up to 24 filaments with multiple units). The AMS 2 Pro’s high-speed filament feeding and precise material management ensure seamless transitions between filaments, enabling:

-

Complex Multi-Material Prints: The H2D can print intricate parts with combinations of rigid materials (e.g., PLA, ABS), flexible materials (e.g., TPU), and dissolvable supports (e.g., PVA). For example, a functional prototype with rigid structural components and flexible joints can be printed in one job without manual intervention.

-

Reduced Print Time: The dual-nozzle system, combined with the AMS 2 Pro’s 60% faster filament feeding, minimizes downtime during material switches. This is particularly impactful for large prints, where frequent material changes would otherwise slow down the process.

-

Support for Dissolvable Materials: The AMS 2 Pro’s active drying system ensures dissolvable filaments like PVA and BVOH remain moisture-free, allowing the H2D to print complex geometries with overhangs that can be easily removed post-printing, saving time on post-processing.

2. Streamlined Workflow with Large Build Volume

The H2D’s large build volume allows for the production of sizable multi-material parts, such as prototypes, architectural models, or production-grade components. The AMS 2 Pro enhances this capability by:

-

Eliminating Manual Filament Changes: With four spools per AMS 2 Pro unit, users can load multiple materials or colors at once, and the H2D automatically switches between them as dictated by the print file. This eliminates the need to pause the printer, reducing human error and saving significant time.

-

Supporting Batch Production: The combination of the H2D’s large build volume and the AMS 2 Pro’s multi-filament system enables efficient small-batch production. For example, a single print job can produce multiple parts with different material properties or colors, maximizing throughput.

3. Enhanced Precision and Reliability

The H2D’s advanced motion control and high-resolution printing capabilities are complemented by the AMS 2 Pro’s precise filament management. The RFID integration ensures that the H2D uses optimal settings for each filament, reducing the risk of print failures due to incorrect temperatures or extrusion rates. The active drying system further enhances reliability by maintaining filament quality, preventing issues like stringing, warping, or clogging during long print jobs.

4. Power and Connectivity Efficiency

The H2D’s ability to directly power one AMS 2 Pro unit eliminates the need for an external power adapter, simplifying setup and reducing cable clutter. This direct integration ensures a stable power supply for the AMS 2 Pro’s drying and feeding systems, maintaining consistent performance during extended print jobs. For larger setups with multiple AMS units, the H2D’s compatibility with serial connections ensures smooth communication and coordination across all units.

Impact on 3D Printing Efficiency

The combination of the AMS 2 Pro’s four-filament spool system and the H2D printer transforms 3D printing efficiency in several key ways:

1. Time Savings Through Automation

The AMS 2 Pro’s automated filament switching, high-speed feeding, and RFID integration eliminate manual tasks, such as swapping spools or configuring material settings. When paired with the H2D’s dual-nozzle system, this automation allows for uninterrupted printing of complex, multi-material designs. For example, a print that requires alternating between four colors or materials can be completed in a single session, saving hours compared to traditional single-filament printers.

2. Reduced Post-Processing

The ability to use dissolvable support materials like PVA, kept in optimal condition by the AMS 2 Pro’s drying system, simplifies post-processing. The H2D’s dual-nozzle setup can dedicate one nozzle to support material, allowing for intricate designs with overhangs that can be easily dissolved, reducing manual cleanup time and improving surface finish quality.

3. Increased Throughput for Prototyping and Production

The H2D’s large build volume, combined with the AMS 2 Pro’s ability to manage multiple materials, enables users to produce larger or multiple parts in a single print job. This is particularly valuable for prototyping labs or small businesses, where rapid iteration and production of functional parts are critical. The system’s efficiency reduces turnaround times, allowing for faster design cycles and market delivery.

4. Versatility for Diverse Applications

The AMS 2 Pro’s four-spool system, expandable to 24 filaments, and the H2D’s dual-nozzle capabilities cater to a wide range of applications, from vibrant multi-color models for art and education to functional multi-material parts for engineering and manufacturing. For instance, a single print job could combine PLA for structural components, TPU for flexible seals, and PVA for temporary supports, all managed seamlessly by the AMS 2 Pro and executed precisely by the H2D.

5. User-Friendly Experience

The integration of the AMS 2 Pro with the H2D simplifies complex multi-material printing, making it accessible to users of all skill levels. The tool-free maintenance, RFID automation, and intuitive Bambu Studio software reduce the learning curve, while the H2D’s advanced features cater to professional users. This balance broadens the appeal of multi-material 3D printing, encouraging adoption across industries.

Conclusion

The Bambu Lab AMS 2 Pro, with its advanced four-filament spool system and seamless integration with the H2D printer, sets a new standard for efficiency in 3D printing. The ability to manage multiple materials and colors with automated switching, active drying, and high-speed feeding streamlines workflows and enhances print quality. When paired with the H2D’s dual-nozzle system and large build volume, the AMS 2 Pro enables users to produce complex, high-quality parts with minimal manual intervention, reduced post-processing, and faster turnaround times. This powerful combination empowers hobbyists, educators, and professionals to push the boundaries of 3D printing, from vibrant multi-color designs to functional multi-material prototypes.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.